The Sealed Quench Furnace (SQF), also known as an Integral Quench (IQ) Furnace, is one of the most dependable and versatile heat treatment systems from HIGHTEMP. It’s commonly used for processes like carburizing, carbonitriding, and hardening.

Built with a sealed and controlled atmosphere, the furnace protects components from oxidation and decarburization during heating. It also features an integrated quench tank, which ensures fast and uniform cooling after the heating cycle.

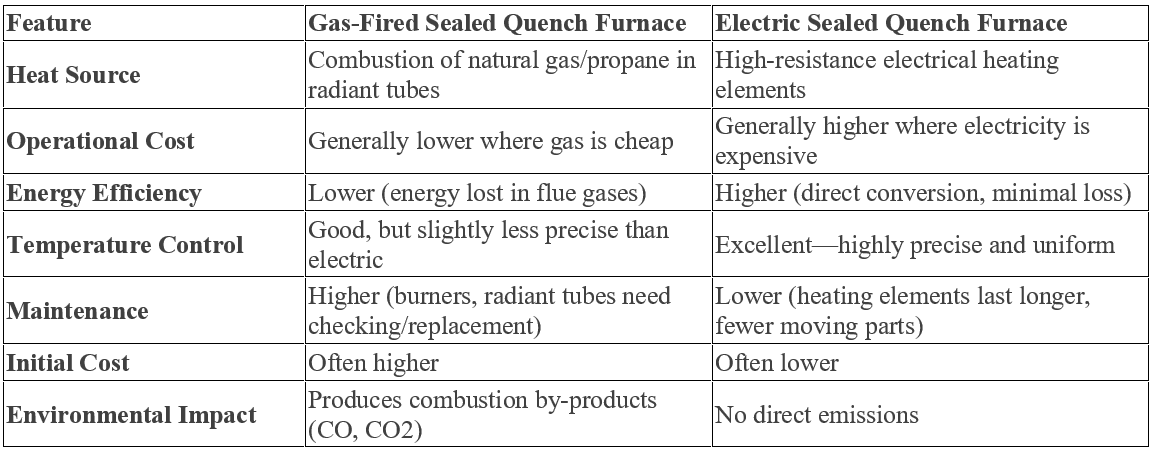

At HIGHTEMP, we offer Sealed Quench Furnaces in two versions — Gas-Fired and Electric. The main difference lies in the heat source, which influences energy efficiency, operating cost, temperature control, and maintenance needs. This allows our customers to choose the best fit for their production requirements.

Gas-Sealed Quench Furnace

Gas-fired Sealed Quench Furnaces (SQFs) generate heat by burning fuels such as natural gas, propane, or LPG through specially designed burners. The combustion happens inside radiant tubes, which keep the flame and its combustion gases separate from the furnace’s controlled atmosphere (such as endothermic gas). This design ensures consistent heating while maintaining a clean and stable process environment inside the furnace.

Advantages of Gas-Fired SQFs

• Lower Operating Costs (Often): In regions where natural gas is significantly cheaper than electricity, the operational cost of a gas-fired furnace is typically lower, making it more economical in the long run despite its lower energy efficiency.

• Faster Heat-Up: Gas burners can often heat the furnace to the operating temperature more quickly than electric elements, which can be an advantage for high-volume production.

• Suitability for High Temperatures: Gas combustion can easily achieve and maintain the high temperatures required for various heat treatment processes.

Electric-Sealed Quench Furnace

Electric Sealed Quench Furnaces (SQFs) use high-resistance heating elements, typically made from materials like Nichrome or APM alloy, to produce heat. Since the heat is generated directly from electrical energy within the furnace chamber, there’s no combustion process involved. This makes electric SQFs cleaner, quieter, and easier to control in terms of temperature uniformity.

Advantages of Electric SQFs

• Superior Temperature Control and Uniformity: Electric elements can be regulated with extremely high precision using systems like Thyristors, offering tighter temperature uniformity and control. This is critical for high-specification parts in industries like aerospace.

• Higher Energy Efficiency: Electric furnaces are highly efficient, converting nearly all of the electrical energy directly into heat inside the chamber, minimizing heat loss.

• Cleaner and Quieter Operation: With no combustion, electric units are cleaner, more environmentally friendly (especially if the electricity is from renewable sources), and operate much more quietly.

• Lower Maintenance: They have fewer complex mechanical components than gas furnaces (no burners, no flue), leading to a longer lifespan for the heating elements and overall less maintenance.

A Side-by-Side Comparison

Both types of Sealed Quench Furnaces serve the same essential purpose — delivering high-quality, controlled atmosphere heat treatment. The key difference lies in the method of heating. At HIGHTEMP, we help customers choose the right solution by evaluating factors such as energy costs, production requirements, and quality standards, ensuring the furnace perfectly aligns with their operational goals.