In modern manufacturing, visibility and controls are critical. As processes become more complex and quality requirements tighter, industries need systems that can monitor operations in real time and respond instantly. This is where SCADA (Supervisory Control and Data Acquisition) systems play a vital role.

SCADA acts as the central nervous system of an industrial plant—connecting machines, processes, and people through data.

What Is SCADA and How Does It Work?

A SCADA system collects real-time data from sensors, instruments, PLCs, and equipment across the plant floor. This data is displayed on user-friendly dashboards, allowing operators to monitor parameters such as temperature, pressure, energy consumption, and system status.

More importantly, SCADA does not just show data—it enables control. Operators can adjust set points, respond to alarms, and manage processes directly from the system.

Control and Monitoring in Real Time

SCADA continuously tracks critical process parameters and immediately highlights deviations. If a value crosses a defined limit, the system triggers alarms or notifications, allowing quick corrective action.

In automated environments, SCADA can also initiate predefined control actions—reducing dependence on manual intervention and minimizing human error. This ensures stable, repeatable operations even in high-volume production.

Optimizing Operations with Data

One of SCADA’s biggest advantages is its ability to turn operational data into actionable insights.

• Historical data and trends help identify inefficiencies

• Predictive maintenance reduces unplanned downtime

• Energy monitoring supports cost and sustainability goals

By understanding how systems behave over time, manufacturers can continuously improve productivity, quality, and equipment life.

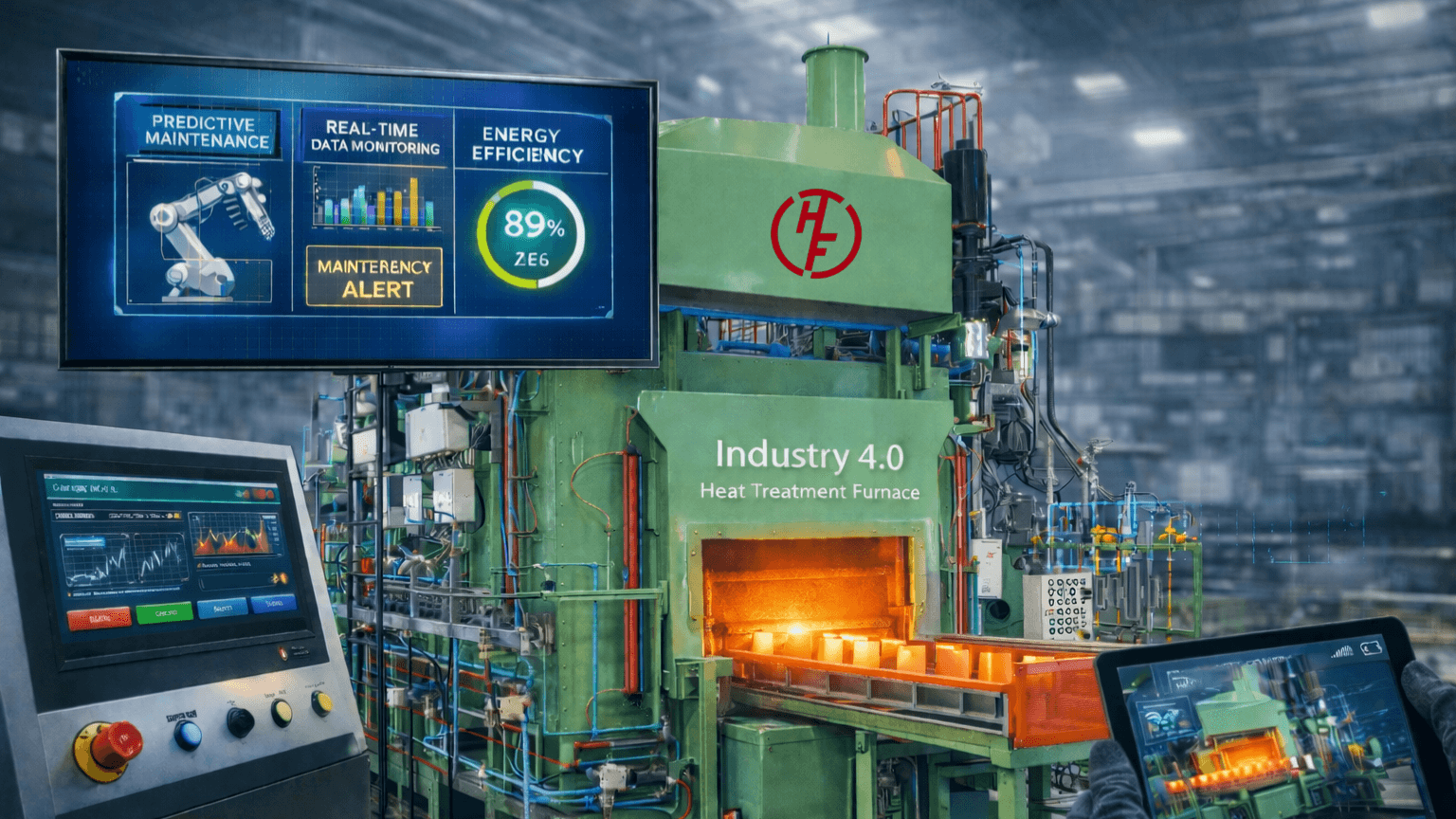

SCADA and Industry 4.0 in Heat Treatment

SCADA is a key enabler of Industry 4.0, especially in heat treatment operations where precision and consistency are critical.

HIGHTEMP’s Smart Furnace 4.0 integrates PLC, SCADA with a few hardware tools to deliver:

• Real-time and remote furnace monitoring

• Automated alerts and maintenance planning

• Centralized data logging and batch reporting

• Improved traceability

This transforms traditional furnaces into smart, connected systems that support data-driven decision-making and higher operational reliability.

SCADA systems are no longer optional—they are essential for efficient, reliable, and future-ready industrial operations. By enabling real-time control, deep process visibility, and continuous optimization, SCADA forms the foundation of smart manufacturing.

When combined with solutions like HIGHTEMP’s Smart Furnace 4.0, SCADA helps industries move from reactive operations to intelligent, predictive, and optimized production.