Heat treatment is essential for enhancing the mechanical properties of shafts, valves, and other long automotive components. These parts demand high strength, wear resistance, and dimensional accuracy. However, if not precisely controlled, heat treatment can introduce defects like distortion, cracking, and decarburization, leading to performance issues or rejections.

1. Distortion

Problem: Shafts and valves are highly susceptible to distortion due to their length and slender geometry. Uneven heating or rapid cooling during processes like carburizing, quenching, or tempering can cause bending, tapering, or warping.

Causes:

• Uneven furnace temperature

• Improper part fixturing or loading

• Aggressive quenching methods

Prevention:

• Use gradual heating and cooling cycles

• Employ rigid fixturing to support length during treatment

• Choose controlled quenching (e.g., gas or oil with agitation control)

• Utilize sealed quench furnaces with uniform thermal zones for better dimensional control

2. Cracking

Problem: Cracks, especially in long components like shafts and spindles, often originate from sharp transitions or material inconsistencies. These typically appear during hardening and quenching and may not be visible until after machining or usage.

Causes:

• High thermal shock from rapid quenching

• Residual stresses due to uneven geometry

• Inherent material flaws or inclusions

Prevention:

• Preheat components before quenching

• Apply intermediate stress-relief cycles

• Avoid sharp edges or sudden cross-sectional changes in design

• Conduct thorough raw material inspection

3. Decarburization

Problem: In precision components like valves or shafts, surface hardness is critical. Decarburization—loss of carbon from the surface during heat exposure—reduces surface wear resistance, making the part prone to early failure.

Causes:

• Prolonged exposure to oxidizing atmospheres at high temperatures

• Inadequate furnace sealing or gas control

Prevention:

• Use sealed quench or vacuum furnaces with inert gas atmospheres (e.g., nitrogen)

• Apply protective coatings or pack carburizing techniques

• Optimize cycle times and avoid unnecessary exposure at peak temperatures

The Role of Controlled Heat Treatment for Long Components

Components like shafts and valves demand precision. Any defect, even minor, can impact performance or lead to rejection.

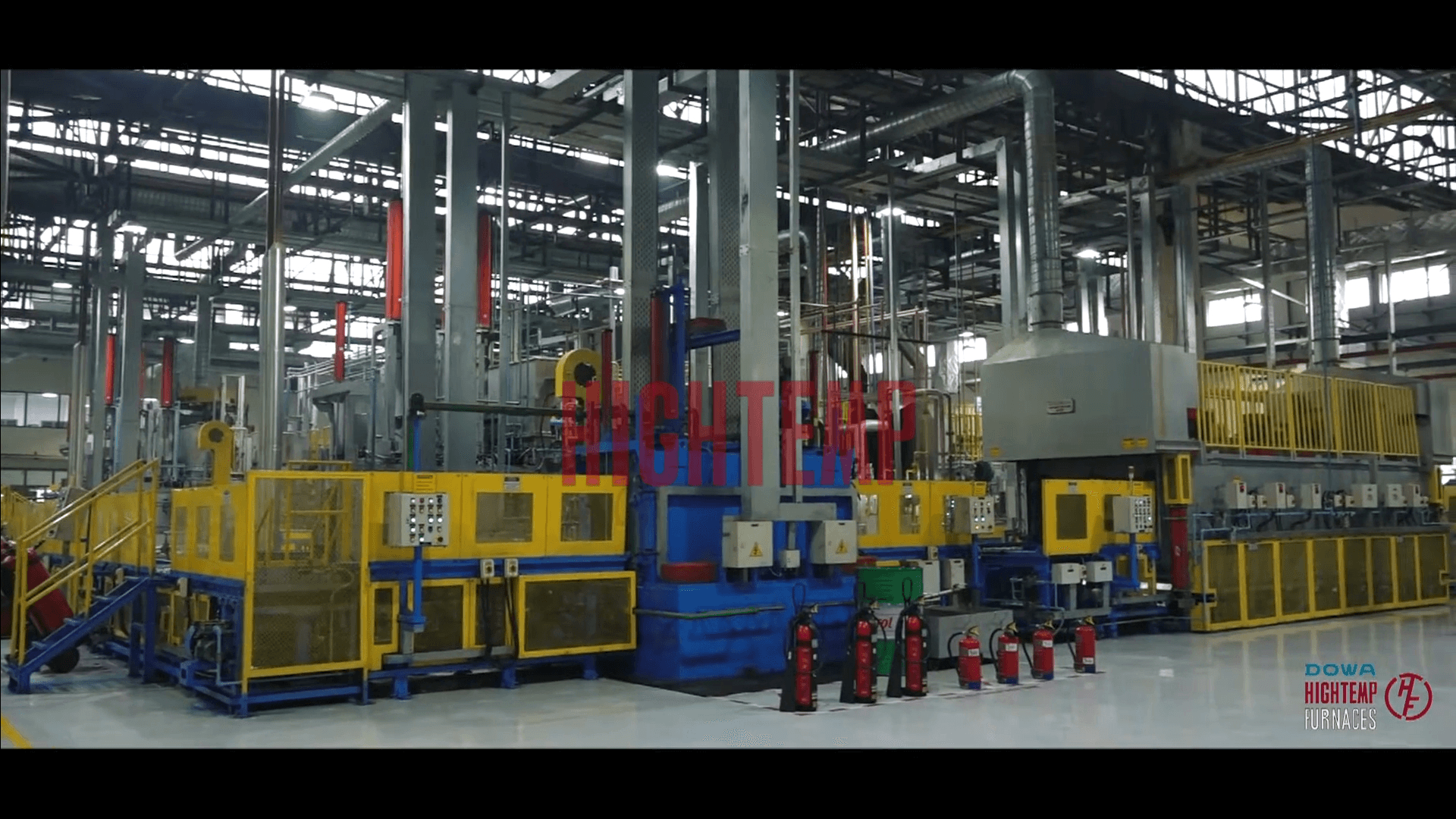

At HIGHTEMP, we specialize in heat treating long-length automotive components with processes including:

• Through hardening

Our advanced furnace systems such as:

• Continuous Lines

offer superior temperature and atmosphere control, ensuring consistent results with minimal defects.

Conclusion

Minimizing distortion, cracking, and decarburization is critical in the heat treatment of shafts, valves, and other elongated automotive parts. Precision in thermal control, fixturing, and atmosphere management ensures component reliability and performance.

Partnering with an experienced provider like HIGHTEMP guarantees that your components are heat treated to exacting standards—efficiently, safely, and defect-free.