Normalizing is a heat treatment process that refines the microstructure of steel by relieving internal stresses and enhancing its mechanical properties. These improved properties include toughness, strength, and ductility. The process involves heating the steel to a temperature above its upper critical transformation temperature, followed by air cooling. The heat treatment performed involves heating the material to a temperature range of 880°C to 950°C, followed by a soak period to ensure uniform temperature distribution, and then cooling in still air.

Industries Served:

Defense Industry

Gears Industry

Bearing Industry

Forging Industry

Material Grades That Can Undergo The

Normalising

Material

Carbon Steels, Tool Steel, Martensitic Steel, Alloys Steel

Material Grade

AISI 1050, 1040, 1020, 1080, 1095 AISI 4140, 4340, 8620, 9310

Normalising Furnaces

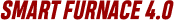

Pit Type Normalising Furnace

HIGHTEMP's Pit Type Normalising Furnace is a specialized heat treatment solution designed to restore uniform grain structures and refine the mechanical properties of metal components. Operating at temperatures typically ranging from 850°C to 950°C, this furnace ensures consistent heating and controlled cooling, essential for reducing internal stresses, improving machinability, and achieving a uniform microstructure. The vertical, pit-type design is ideal for processing long or large components such as shafts, spindles, and forged parts, making it a preferred choice in automotive, aerospace, and heavy engineering industries. With precise temperature control and energy-efficient operation, the Pit Type Normalising Furnace enhances the overall performance and durability of treated components.

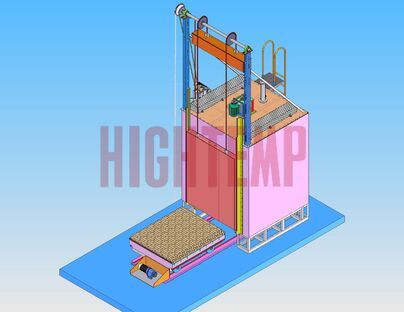

Bogie Hearth Furnace

HIGHTEMP's Bogie Hearth Furnace is designed for the heat treatment of heavy and large components. Equipped with a bogie, the furnace simplifies the loading and unloading process, making it ideal for applications requiring precision and uniform heating. The insulation and efficient heating systems ensure energy savings while maintaining superior performance. This furnaces can be customized with single or double doors and single or double bogies to meet specific user requirements. Materials are loaded onto the bogie using an EOT crane or mechanical devices, and the loaded bogie is moved into the furnace via an electro-mechanical rack-and-pinion or rope-and-drum bogie drive mechanism, ensuring smooth and efficient operation.

Integral Batch Sealed Quench Furnace

Sealed Quench Furnace (SQF) is used for high-precision heat treatment primarily in auto components industry. This allows heat treatment for carbon steel to reach the desired hardness and strength. The furnace feature allows the materials to be processed in batches rather than continuous operation. HIGHTEMP is the leading manufacturer of Sealed Quench Furnace in India that provides a global clientele, with sales volume exceeding 500+.