Carbonitriding is a surface hardening process that introduces both carbon and nitrogen into the outer layer of steel, enhancing its wear resistance, fatigue strength, and surface hardness. This thermochemical treatment is primarily applied to low-alloy and carbon steels, resulting in improved wear resistance, fatigue strength, and increased hardness of the treated material.

Industries Served:

Gears Industry

Auto components Industry

Aerospace Industry

Material Grades That Can Undergo The

Carbonitriding

Material

Alloy Steel, Carbon Steel

Material Grade

AISI 4140, 4340

Carbonitriding Furnaces

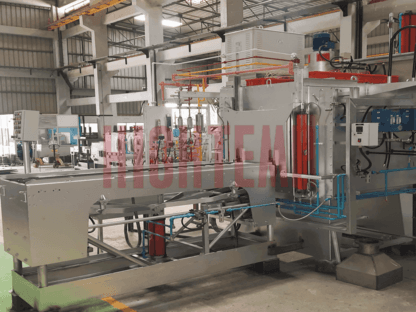

Integral Batch Sealed Quench Furnace

Sealed Quench Furnace (SQF) is used for high-precision heat treatment primarily in auto components industry. This allows heat treatment for carbon steel to reach the desired hardness and strength. The furnace feature allows the materials to be processed in batches rather than continuous operation. HIGHTEMP is the leading manufacturer of Sealed Quench Furnace in India that provides a global clientele, with sales volume exceeding 500+.

Pit Type Gas Carburising Furnace

HIGHTEMPs Pit Type Gas Carburising Furnace is a specialized heat treatment solution designed for the gas carburising process, where carbon is diffused into the surface layer of steel components to enhance their hardness and wear resistance. Operating at temperatures typically ranging from 850°C to 950°C, our furnace ensures precise control over carburising depth and temperature uniformity. The vertical, pit-type design is ideal for treating long or large components such as shafts, gears, spindles, and axles, making it widely used in industries like automotive, aerospace, and heavy engineering. The furnace operates under a controlled atmosphere, ensuring consistent results and superior surface properties while maintaining core toughness.