- Continuous operation allows for efficient, high-volume processing, meeting the demands of large-scale production.

- Optimized heat distribution and superior insulation minimize energy consumption, lowering operating costs.

- Automated operation reduces the need for manual labor, streamlining production and improving efficiency.

- High-quality materials and robust design ensure long-lasting, reliable performance, even under continuous use.

- Capable of treating a wide range of steel grades and components, including gears, shafts, and camshafts, for various industries.

- Optimized processes and reduced energy consumption contribute to sustainable and environmentally responsible manufacturing practices.

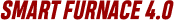

The HIGHTEMP Continuous Gas Carburising Furnace is an advanced heat treatment solution designed for high-volume production and precise carburising of components. Built for efficiency and consistency, this furnace uses a continuous single-track design, making it ideal for industries that demand superior quality, cost-effective operations, and high throughput. Operating at temperatures of up to 950°C, the furnace introduces carbon into the surface layer of steel components to improve hardness, wear resistance, and fatigue strength, while maintaining a tough core. With options for endothermic gas or nitrogen-methanol atmospheres, it ensures optimal carburising conditions tailored to specific requirements.

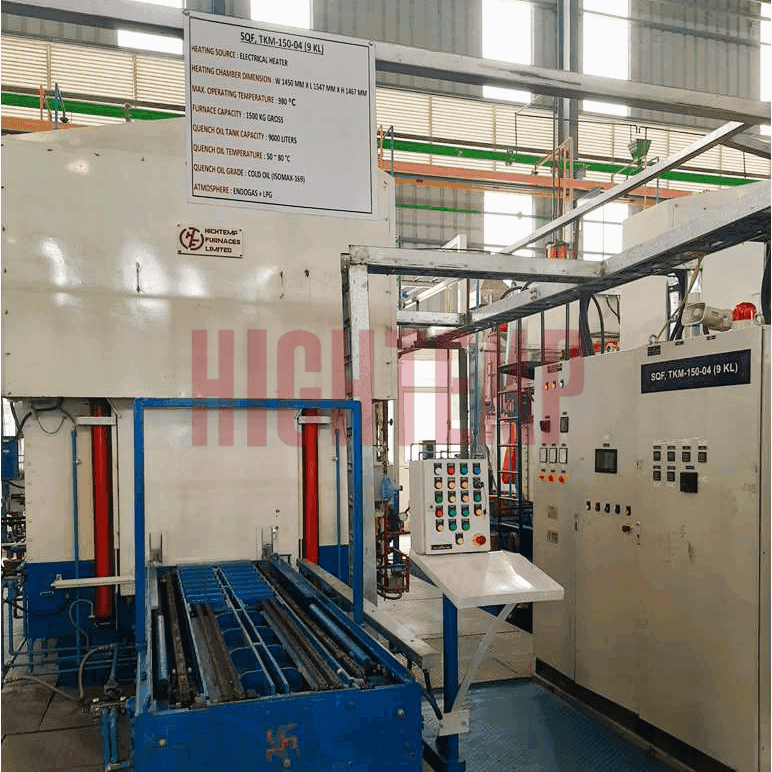

The Sealed Quench Furnace is a high-performance heat treatment system designed for austempering, carburising, and tempering. Ideal for components like gears, shafts, clutch plates, springs, fasteners, and crankshafts, it delivers superior wear resistance, toughness, and fatigue strength. Austempering is a specialized process that transforms steel into an ausferrite microstructure, enhancing toughness, wear resistance, and fatigue strength with minimal distortion. This makes it ideal for components that require superior mechanical performance. This furnace can perform other heat treatment processes, including hardening, carbonitriding, normalizing, nitrocarburizing, nitriding, neutral hardening, annealing, and bright hardening.

The Sealed Quench Furnace is compatible for heat treatment of material grades like EN8, EN9, EN31, 16MnCr5, 20MnCr5, SAE 4140, and SAE 8620. This furnace ensures precise atmosphere control and uniform heating for consistent results. Whether strengthening automotive gears or hardening industrial tools, it excels in enhancing mechanical properties while minimizing distortion. In this Tempering is a crucial step that follows processes like carburising or case hardening, designed to relieve internal stresses, reduce brittleness, and enhance the overall toughness of components. Similarly, Austempering process ensures an optimal balance between hardness and ductility, making treated parts more durable and resistant to impact. This furnace can perform other heat treatment processes, including hardening, carbonitriding, normalizing, nitrocarburizing, nitriding, austempering, neutral hardening, annealing, and bright hardening.