In today’s fast-paced manufacturing environment, automation is no longer a luxury—it’s a necessity. Industries such as automotive, aerospace, and heavy engineering are increasingly turning to automation to enhance efficiency, consistency, and safety in their operations. One critical area that’s benefiting from this transformation is heat treatment.

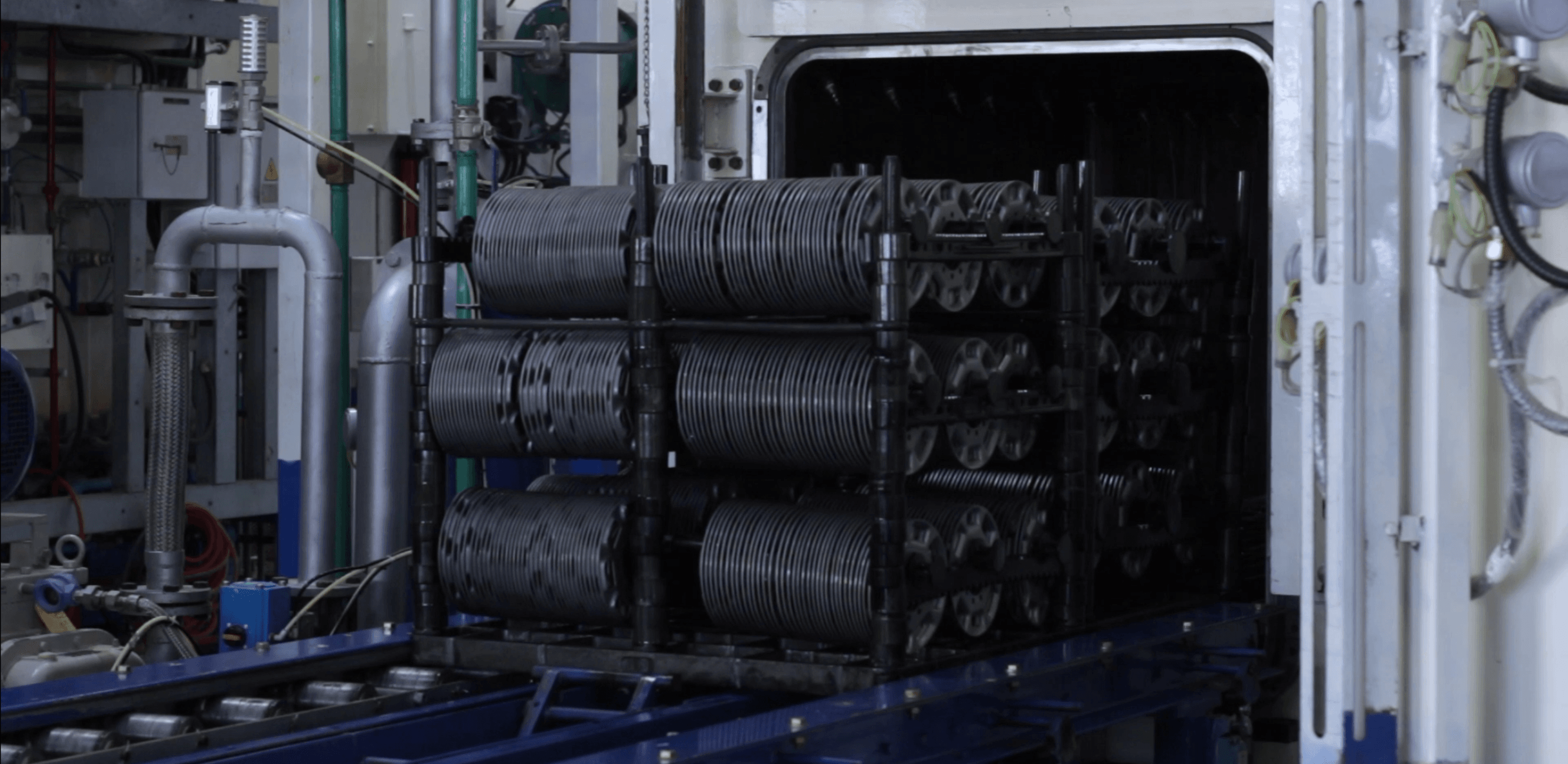

Modern heat treatment furnaces are no longer just large boxes that get hot. With automation, they have become intelligent systems capable of precise control, real-time monitoring, and seamless integration with plant-wide processes.

1. Precision and Consistency in Process Control

Automation allows for accurate control of time, temperature, and atmosphere—the three critical parameters of heat treatment. Advanced PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems help ensure:

• Uniform heating and cooling

• Repeatable process cycles

• Minimal human error

• Real-time adjustments based on sensor feedback

2. Energy Efficiency and Operational Cost Savings

Automated systems optimize furnace operation by reducing idle time, overheating, and excess energy use. They can:

• Schedule loads efficiently

• Automatically shut down or switch to standby during low demand

• Monitor energy consumption in real time

3. Enhanced Safety and Operator Comfort

Traditional furnace operations can pose risks due to high temperatures, manual handling, and potential gas leaks. Automation improves safety by:

• Remote operation is possible via HMI/SCADA systems

• Safety interlocks prevent accidents

• Sensors detect gas leaks or abnormal conditions

• Alarms and emergency shutdown features are integrated

4. Real-Time Monitoring and Predictive Maintenance

Today’s automated systems allow for continuous monitoring of furnace health and performance:

• IoT sensors track furnace zones and part temperatures

• Data logs are maintained for every cycle

• Maintenance alerts help prevent downtime

• Load tracking ensures full traceability

5. Industry 4.0 Integration and Smart Manufacturing

Automated furnaces can be integrated into plant-wide MES (Manufacturing Execution Systems) or ERP systems, enabling:

• Full traceability of heat-treated parts

• Automated job tracking and reporting

• Real-time production dashboards

• Seamless workflow from scheduling to final inspection

From precision and safety to efficiency and smart integration, HIGHTEMP’s automated furnace solutions are transforming the way heat treatment is done:

• Sealed Quench Furnaces – Ideal for case hardening and carburizing with consistent, controlled results

• Continuous Furnaces – Designed for high-volume production with minimal downtime