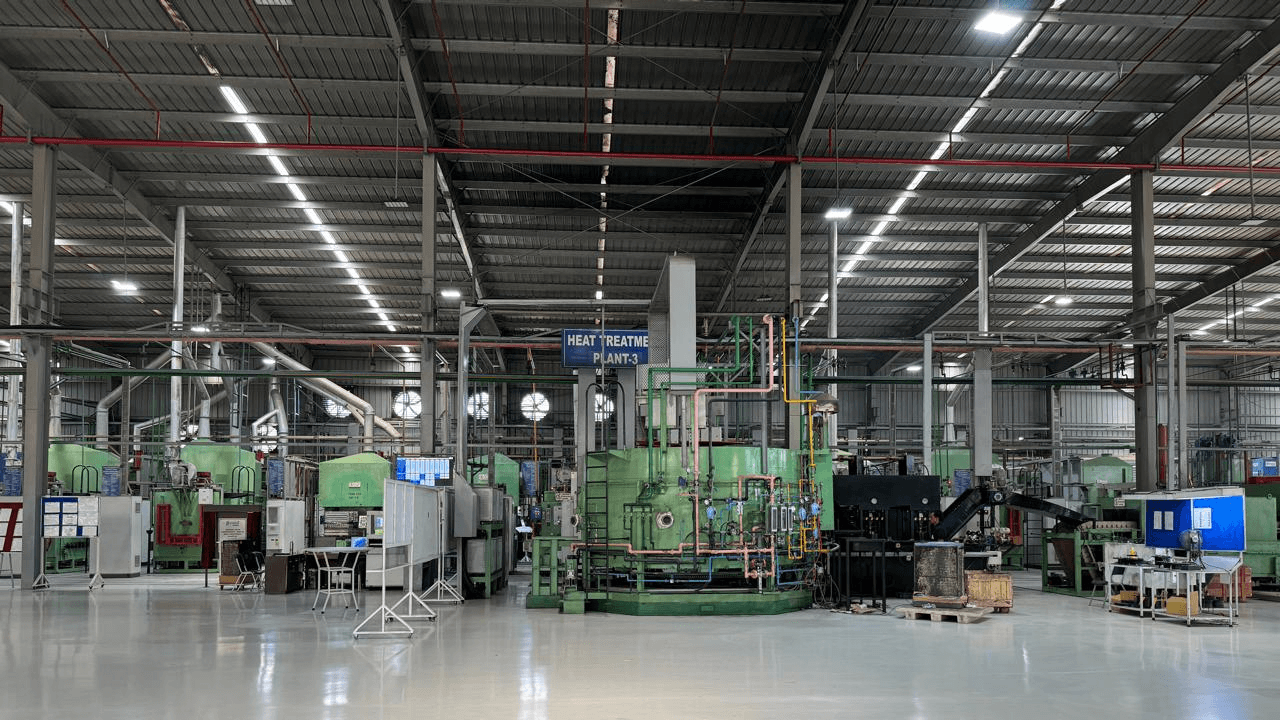

Rotary Hearth Furnaces (RHF) play a vital role in modern heat treatment, serving industries such as automotive, aerospace, and forging. They offer uniform heating, precise temperature control, and efficient processing of components, making the choice of the right furnace crucial for the best results.

Gas-Fired Rotary Hearth Furnaces

Gas-fired RHFs use burners to generate heat and rely on a rotating hearth to circulate hot gases uniformly.

Key Advantages:

• High Throughput: Ideal for industries with large-scale production like automotive and forging.

• Uniform Heating: The rotating hearth and gas flow ensure even temperature distribution across large components.

• Versatile Applications: Perfect for reheating, hardening, and surface treatments such as carburizing.

• Energy Efficiency: Modern gas systems are optimized for fuel savings and reduced emissions. Gas-fired RHFs are typically preferred due to high throughput, versatility, and lower operating costs for large batches.

Industries & Applications:

• Automotive: Gears, shafts, and bearings requiring hardening or carburizing.

• Forging: Heating carbon and alloy steels before forging operations.

• Aerospace: Components where high-temperature heating is needed for precision alloys.

Electrically Heated Rotary Hearth Furnaces

Electrically heated RHFs use high-quality electric heating elements to achieve precise, uniform temperatures.

Key Advantages:

• Precise Temperature Control: Electric elements allow exact regulation, making them ideal for high-precision industries.

• Low Emissions: Environmentally friendly with minimal greenhouse gas output.

• Energy Efficient for Small-to-Medium Loads: Reduces operating costs in industries where gas supply may be limited.

• Consistent Results: Rotating hearth ensures uniform heat distribution for complex components.

Industries & Applications:

• Automotive: Specialty parts like high-performance engine components.

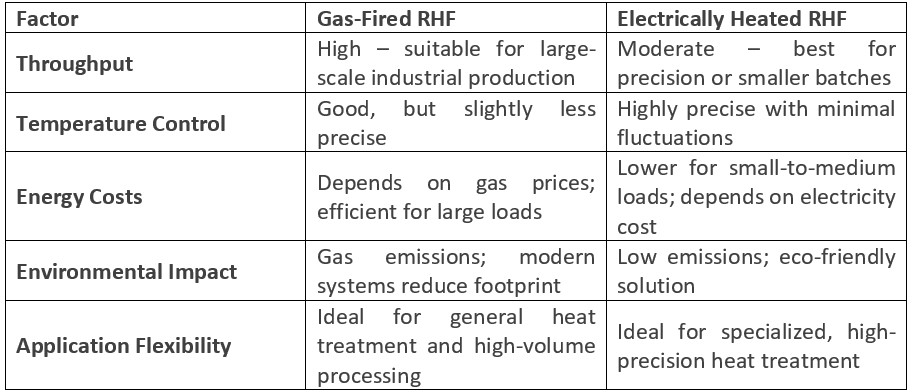

Key Considerations When Choosing Between Gas and Electric

HIGHTEMP offers both Gas-Fired and Electrically Heated Rotary Hearth Furnaces, designed for:

• Uniform heat distribution with rotating hearths

• Precise temperature control for consistent results

• Durability for processing large components at up to 900°C

• Customizable options for gas systems, loading, and unloading

Whether you need to process automotive gears, aerospace turbine blades, or forged steel components, HIGHTEMP provides tailored solutions to meet your exact industrial requirements.