Case hardening involves adding carbon to the surface layer of low-carbon steel components. This is done to increase the hardness of the exterior without affecting the core toughness. Case hardening is a vital heat treatment process used to enhance the surface hardness and wear resistance of components while maintaining a tough and ductile core. This method is especially effective for parts subjected to heavy wear, friction, and impact—making it a popular choice in the automotive, aerospace, and industrial machinery sectors.

The generic heat treatment cycle of case hardening for auto components like SLIDER, CONTROL SPOOL, STUD BOLT, SPUR GEAR, and DIFF SPIDER.

1. Pre-cleaning – The part is cleaned to remove contaminants.

2. Heating – The component is heated in a carbon-rich environment, usually between 870°C to 950°C.

3. Carburizing – Carbon atoms diffuse into the steel surface.

4. Diffusion Holding – The part is held at temperature to allow deeper penetration.

5. Quenching – Rapid cooling in oil or polymer to lock in hardness.

6. Tempering – Reheating to reduce brittleness and stress.

Role of Case Hardening in automotive components

SLIDER A slider is a mechanical component used in systems like gearboxes and actuators, where it moves back and forth along a surface under continuous friction and contact stress. Case hardening plays a crucial role in enhancing the performance and durability of the slider. By hardening only the outer surface, it provides high wear resistance, allowing the slider to withstand constant friction without degrading.

CONTROL SPOOL A control spool is a key component in hydraulic and pneumatic systems, responsible for directing the flow of fluid to control the movement of actuators. It operates under high pressure and constant friction, as it slides within a valve body. Case hardening significantly improves the performance of control spools by increasing the surface hardness, which helps resist wear, scoring, and erosion caused by continuous contact with pressurized fluids. Retaining core toughness allows the spool to absorb internal loads without compromising its structural integrity.

STUD BOLT A stud bolt is a threaded fastener used in high-stress applications like engines, turbines, and heavy machinery, where it must withstand repeated tightening, vibration, and load. The role of case hardening in stud bolts is to improve surface hardness, particularly at the threads, which are the most wear-prone areas. This enhanced hardness helps resist wear, galling, and thread deformation, especially during assembly and disassembly. Meanwhile, the core remains tough and ductile, allowing the bolt to absorb tensile and dynamic loads without breaking.

SPUR GEAR A spur gear is a critical component that transmits torque between parallel shafts. Case hardening is applied to the gear teeth to create a hard, wear-resistant outer layer that protects against surface damage like abrasion and fatigue. Meanwhile, the gear’s core remains soft and tough, allowing it to absorb impacts and prevent brittleness. This balance of a hard surface and resilient core helps spur gears operate efficiently under heavy loads and reduces the risk of tooth failure, thereby extending the gear’s overall lifespan.

DIFF SPIDER A differential spider is a key part of a vehicle’s differential, helping to distribute torque between the wheels while allowing them to rotate at different speeds. Case hardening plays an important role by giving the spider’s surface a hard, wear-resistant layer that protects it from friction and stress during operation. The inner core retains strength and durability, allowing it to absorb impact and withstand heavy loading without fracturing.

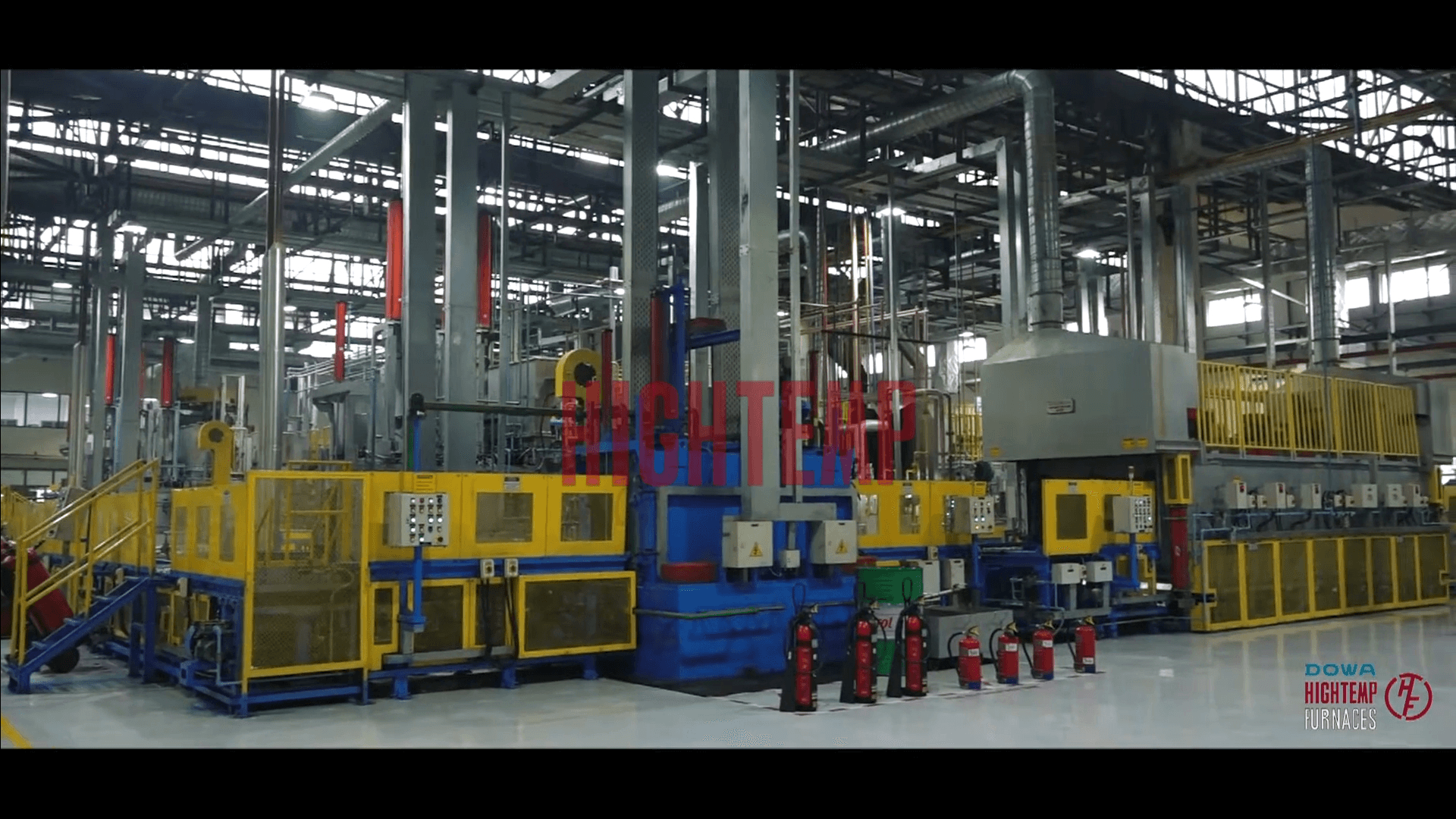

For case hardening heat treatment, the commonly used furnaces are

Continuous Gas Carburising Furnace

If you're working with parts like the slider, control spool, stud bolt, spur gear, or diff spider, case hardening is a proven heat treatment process provides excellent hardness. With precise control of the heat treatment cycle, we ensure that each part meets its design requirements and stands the test of time.