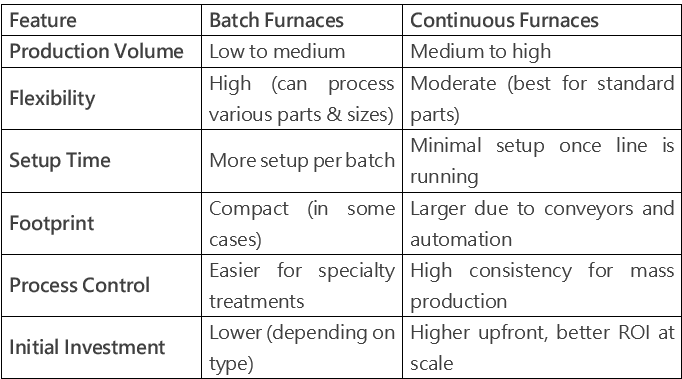

Selecting the appropriate furnace type is a key decision in any heat treatment operation, as it directly impacts the quality, efficiency, and consistency of the final components. The two primary furnace categories—Batch Furnaces and Continuous Furnaces—offer distinct advantages depending on production scale, part complexity, and process goals.

What is a Batch Furnace?

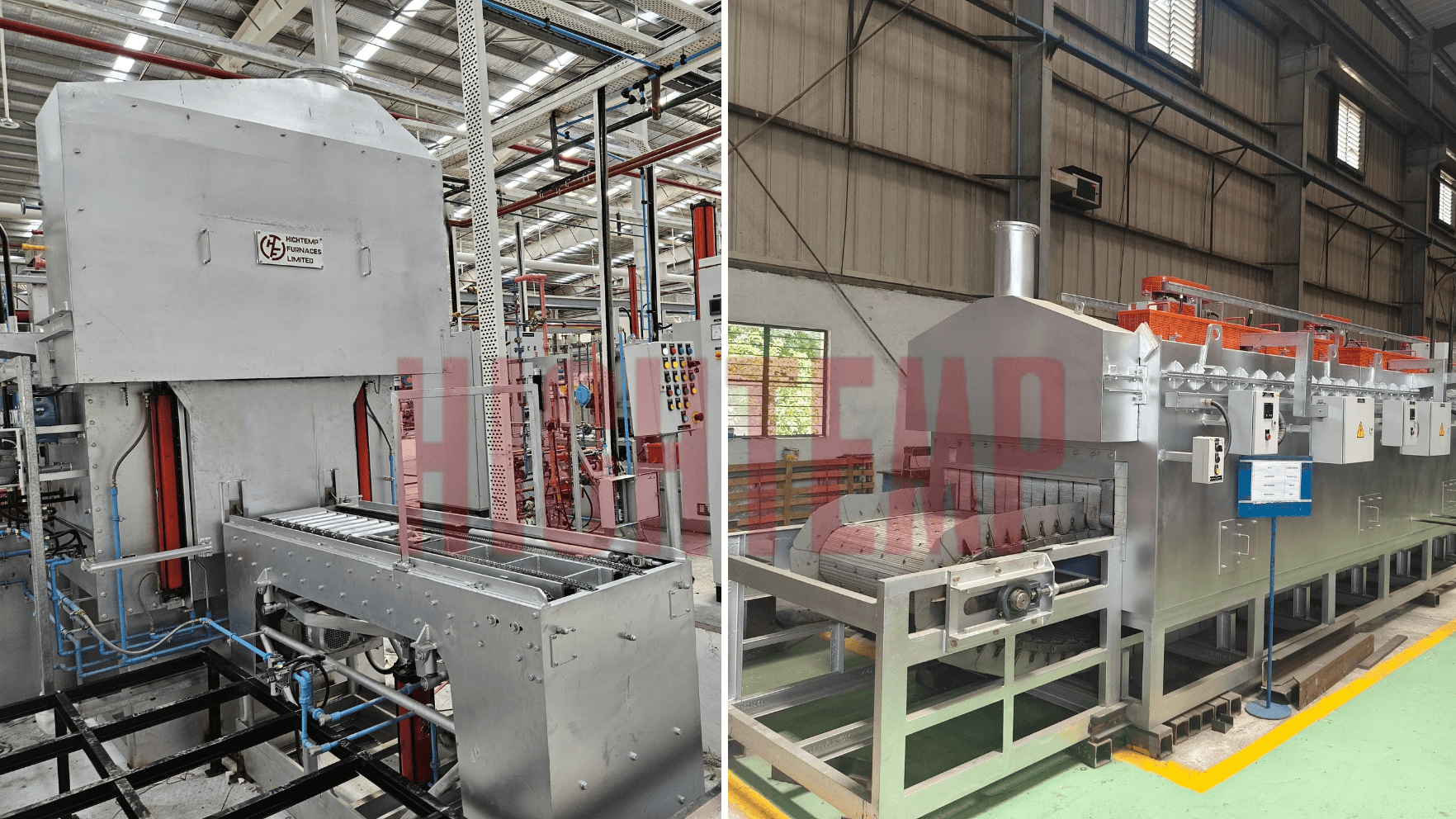

Batch Furnaces (also known as static furnaces) are designed to process parts in lots or "batches." The entire load is placed into the furnace, treated, and then removed as one unit.

Common Batch Furnaces:

• Integral Sealed Quench Furnace (TKM)

• Bogie Hearth Furnace

• Pit Type Furnace

• Drop Bottom Furnace (Aluminum Solution Treatment)

What is a Continuous Furnace?

Continuous Furnaces are designed for high-volume, uninterrupted production. Components move through the furnace on a conveyor system (mesh belt, pusher, roller hearth) and pass through various heating zones in a streamlined flow.

Common Continuous Furnaces:

• Mesh Belt Conveyor Furnace

• Continuous Sealed Quench Furnace

• Rotary Hearth Furnace

• Pusher Furnace

• Aluminum Melting and Holding Furnaces

Key Differences: Batch vs. Continuous

When to Choose a Batch Furnace

Choose a Batch Furnace if:

• You process low volumes or custom orders

• You need process flexibility

• You handle large, heavy, or complex components (like castings or forgings)

• You frequently change materials or treatment types

Example: The Bogie Hearth Furnace is ideal for heat treating heavy railway and automotive components, where custom cycle programming and loading flexibility are essential.

When to Choose a Continuous Furnace

Choose a Continuous Furnace if:

• Your production is high-volume and standardized

• You need fast throughput and consistent quality

• Downtime must be minimized

• You have long-term, repetitive part processing

Example:

The Continuous Mesh Belt Conveyor Furnace is perfect for processing automotive fasteners, stampings, and small precision components with consistent heat distribution and minimal manual handling.

Which One is Right for You?

The answer depends on a combination of:

• Production volume

• Part type and geometry

• Required flexibility

• Available floor space

• Budget and return expectations

If you're processing a mix of part sizes and materials, or doing R&D and low-volume work, batch furnaces provide versatility.

If you're running high-volume automotive lines with tight delivery schedules, continuous furnaces deliver efficiency and repeatability.

At HIGHTEMP Furnaces Ltd, we manufacture and supply both batch and continuous furnace systems to suit diverse industrial needs. Our solutions include:

• Integral Sealed Quench Furnace (TKM) for batch carburizing and hardening

• Continuous Sealed Quench Furnace for mass production

• Mesh Belt Conveyor Furnaces for bright hardening and tempering

• Drop Bottom Furnaces for aluminum heat treatment

• Bogie Hearth Furnaces for large castings and forgings

Choosing the right furnace plays a vital role in improving process reliability, ensuring consistent product quality, and maximizing operational efficiency. Whether your goal is to increase production volume or focus on specialized heat treatment applications, selecting between batch and continuous furnace systems should be guided by your long-term manufacturing objectives and process requirements.