Get a Custom Quote

Leading Heat Treatment Solutions

Cutting-Edge Furnace Systems and Exceptional Commercial Heat Treatment Services Backed by Global Expertise.

"Hightemp is carrying out variety of Heat Treatment processes on many of our critical components & has been consistent on Quality."

Get a Custom Quote

"Hightemp is carrying out variety of Heat Treatment processes on many of our critical components & has been consistent on Quality."

We Manufacture

Industrial Heat Treatment Furnaces

Advanced Sealed Quench Furnaces for Precision Heat Treatment

Sealed Quench Furnace

01

Enhance Your Production Efficiency and Quality with Our State-of-the-Art Furnaces

Sealed Quench Furnaces are essential for high-precision heat treatment processes in various industries, including metalworking, automotive, and aerospace. Our furnaces are designed to deliver consistent, reliable performance.

Sealed Quench Furnace

| model | gross loading | effective dimensions |

|---|---|---|

| TKM-80 | 600 | 1230L x 660W x 500H |

| TKM-100 | 700 | 1230L x 760W x 650H |

Applications

Carburising

Hardening

Carbo Nitriding

Case Hardening

Annealing

Bright Hardening

Normalizing

Nitro Carburising

Features

Uniform Heating : Achieved through closely spaced radiant tubes positioned on both sides from the top, with options for either electric or gas-fired radiant tubes.

Advanced Control Systems : Features fully automated controls including PLC, Thyristor with PID temperature regulation, carbon potential controller with proportional valve, touch screen graphic operator panel with alarm annunciation, and multi-point temperature recording.

Consistent Temperature and Atmosphere : Ensured by a cast integral fan for maintaining uniform conditions.

Robust Construction : Options available for silicon carbide skids or heat-resistant steel T-rails.

Efficient Operations : Equipped with pneumatically operated doors, elevators, and more.

Versatile Atmosphere Options: Capable of using Endo gas, Nitrogen-Methanol, or Fine Carburising Process atmospheres.

Integrated and Compact Design: Incorporates washing, tempering, and material handling equipment, all offered at economical prices.

Turnkey Solutions: Includes complete project execution with process knowhow.

Safety Features: Comprehensive alarms and annunciation with interlocks to ensure operational safety.

Cost-Effective Maintenance: Low-cost, easily available spare parts.

Revolutionary Semi-Continuous Sealed Quench Furnaces for Maximum Efficiency

Semi Continuous Furnace S-TKM

02

Boost Your Production with HIGHTEMP's Advanced Super-TKM Series

HIGHTEMP presents the ground-breaking Super-TKM series, designed for high productivity. Combining the best of batch and continuous furnace technologies

Semi Continuous Furnace S-TKM

| model | gross loading | effective dimensions |

|---|---|---|

| S-TKM80 | 275 | 615L x 660W x 600H |

| S-TKM100 | 360 | 615L x 760W x 720H |

Applications

Carburisingg

Hardening

Carbo Nitriding

Case Hardening

Annealing

Bright Hardening

Normalizing

Nitro Carburising

Advantages

Triple Productivity : Achieves three times the productivity of traditional batch furnaces.

Compact Footprint : Occupies the same space as a batch furnace.

Cost-Efficient : Lower operating costs compared to batch furnaces.

Flexible Operation: Features a roller hearth design for operational versatility.

Proven Performance: Over 5 installations currently operating in India.

Other Products

Why Choose Us..

Leader In Heat Treatment Furnaces

Our strategic partnerships with renowned companies like Dowa Thermotech Co. Ltd (Japan), Meapforni (Italy), Sanken Hiroshima Japan, AFC-Holcroft (USA), Pyradia (Canada), TTI Group Ltd and Vac Aero International (USA) ensure access to the latest technologies and process innovations.

Proven Track Record

HIGHTEMP has a long history of expertise in the field, having manufactured and supplied more than 2000 furnaces all over the world.

Comprehensive Solutions

HIGHTEMP offers both Atmospheric Heat Treatment Furnace Systems and Commercial Heat Treatment, catering to a wide range of industry needs.

Commitment to Quality

Regular quality audits and a sustained emphasis on compliance ensure consistent quality and customer satisfaction.

State-of-the-Art facilities

We have a comprehensive furnace manufacturing facility covering 100,000 sq ft. Our Commercial Heat Treatment Divisions span 650,000 sq ft

Hear from our clients

Testimonials

Committed to exceeding our

Customer expectations

Our Certifications

Committed to exceeding our

Customer expectations

Our Certifications

Top Automotive brands trust us for their Heat Treatment Solutions.

Our Clients

Leading the Way in

Heat Treatment Solutions

Incorporated in 1970, HIGHTEMP a subsidiary of Dowa Thermotech Company Ltd, Japan, has grown steadily from building small ovens and industrial furnaces to becoming one of India’s leading manufacturers of Heat Treatment Furnaces.

At HIGHTEMP, we prioritize excellent management practices, strict adherence to global regulatory standards, and a steadfast commitment to efficient manufacturing processes. Quality is the cornerstone of every product, process, and service we offer.

As we step into a new decade, HIGHTEMP is poised to expand its product and service offerings and explore eco-friendly ventures like renewable energy, reflecting our commitment to a greener planet.

Leading the Way in

Heat Treatment Solutions

Incorporated in 1970, HIGHTEMP a subsidiary of Dowa Thermotech Company Ltd, Japan, has grown steadily from building small ovens and industrial furnaces to becoming one of India’s leading manufacturers of Heat Treatment Furnaces.

At HIGHTEMP, we prioritize excellent management practices, strict adherence to global regulatory standards, and a steadfast commitment to efficient manufacturing processes. Quality is the cornerstone of every product, process, and service we offer.

As we step into a new decade, HIGHTEMP is poised to expand its product and service offerings and explore eco-friendly ventures like renewable energy, reflecting our commitment to a greener planet.

Location: HIGHTEMP FURNACES LIMITED, Furnace Manufacturing & Commercial Heat Treatment

1C, 2nd Phase, Phase -1, Peenya Industrial Area, Bengaluru 560058

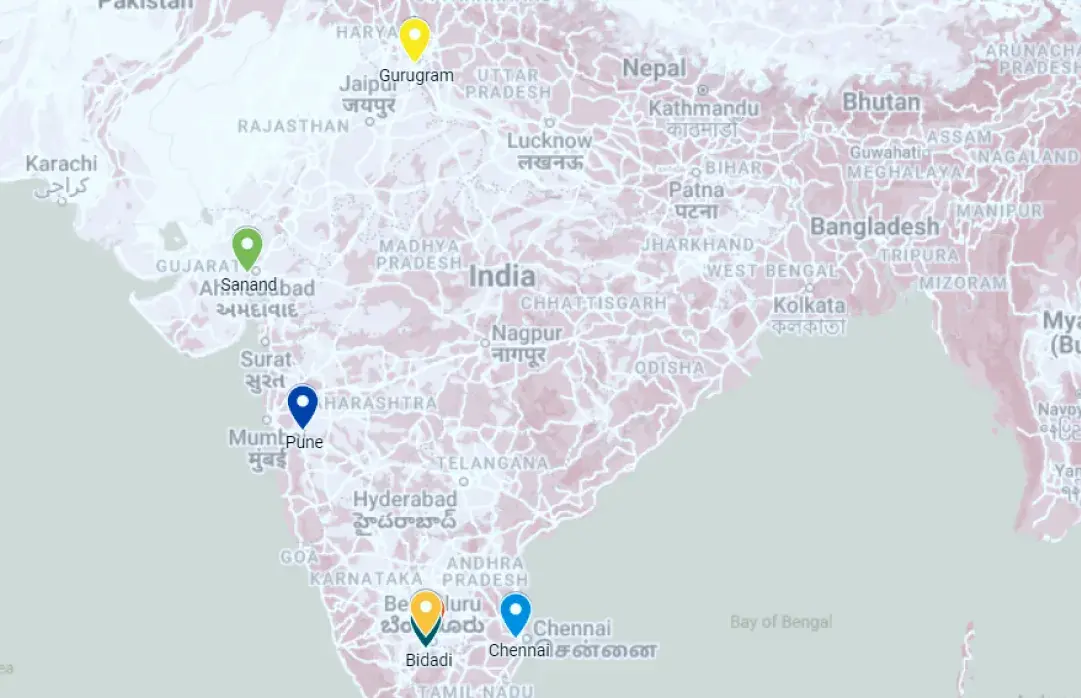

Other Plants: Nelamangala, Bidadi, Chennai, Pune, Sanand, Gurugram.